Contact Us (866) 235-2472 info@bel-air-cases.com

Shipping Cases: 5 Reasons To Buy A Bel-Air Case

When it comes to protecting your valuable equipment during transit, not all shipping cases are created equal. Bel-Air Cases have set the standard for durability, reliability, and customizability in the world of heavy-duty plastic shipping cases for equipment.

Whether you’re shipping delicate instruments across the country or rugged equipment to remote job sites, Bel-Air offers unmatched protection designed to withstand the toughest conditions. In this article, we’ll explore the top 10 reasons why investing in a Bel-Air case is the best decision you can make for safeguarding your equipment.

1. Custom Equipment Cases Offer Better Protection

An off-the-shelf case often can be a good option for inexpensive items that are easy to replace. However, if you have expensive equipment, you need shipping and transport cases that can handle the bumps and bruises typical of transport, a custom case is typically a much better option.

Our custom shipping cases for equipment are built around whatever you need to place inside the case. We can design just about any case configuration you might need. Just give us the specs for your equipment and we will design a case that meets all of your needs.

At Bel-Air, we also build cases to ATA standards, so if you’ve been searching for a custom ATA case, we can help. Our cases meet ATA standards, and we can design cases to meet most MIL specs. Through the years, we have designed many cases for military and aerospace clients and our design and production teams have extensive experience building cases to meet these exacting specifications.

2. Custom Interior Foam Cushions Your Equipment

While the exteriors of our heavy duty shipping cases are built to handle just about any extreme, our quality interior foam adds an extra layer of insurance, absorbing impacts and cushioning every inch of your equipment.

Unfortunately, many case manufacturers will sell cases that include a cheap chunk of diced foam, but this forces the customer to create cavities for their equipment and these cavities likely won’t provide an ultimate layer of protection. At Bel-Air Cases, this type of mediocrity is just not an option.

Instead, we design custom foam inserts for each of our shipping cases and, as with our case exteriors, we build this foam interior around your equipment, so that every component is cushioned and protected. Additionally, we use the highest quality foam available, which means the interior compartments will last for many years to come.

Cheap pick-and-pluck foam, which is common with off-the-shelf cases (and sometimes even custom cases) tends to break down quickly and will need to be replaced every couple of years. To be honest, if you find a custom case manufacturer that opts for cheap diced foam, we recommend finding another manufacturer. If you are paying for a custom plastic case with foam, you should expect to have the highest quality custom foam as a part of that purchase price.

3. We Use The Highest-Quality Case Materials

Did you know that Bel-Air Cases was the first company to produce vacuum-formed equipment cases? Back in those days (the 1960s), the plastics industry was booming and the main material we use, high-density polyethylene (HDPE) was a relatively new plastic, invented in the 1950s by chemists at Philips Petroleum.

Vacuum-forming allows us to create HDPE shells of virtually any size, and HDPE is the perfect choice for equipment cases for a variety of reasons. For instance, HDPE is known for its exceptional level of durability as well as its impact resistance. HDPE also is weatherproof and resistant to temperature extremes as well as UV rays and moisture as well as many chemicals and solvents.

4. Plastic Cases Are Lightweight & Easy To Maneuver

HDPE has a high strength-to-weight ratio. So, while HDPE is a very strong material, it’s also extremely lightweight. This makes it easier for consumers to carry our shipping cases and carrying cases but also can reduce your shipping and freight costs significantly.

5. Stylish Designs & Many Custom Features

While we can customize the size for our shipping cases, that’s just one facet of customization we can deliver. We also have a huge selection of locks, latches, feet and hinges. Want equipment cases with wheels? No problem. Need a shipping case or a plastic carrying case with a handle? Done.

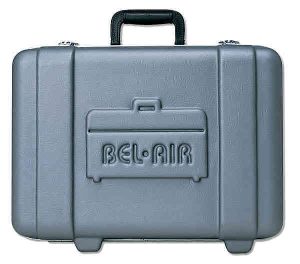

We also can add molded-in logos to any Bel-Air, and this can add an extra level of professionalism to your case. Additionally, we can add engraved plates or custom decals to any case. Case colors also can be customized. Silver and black are our standard colors, but we have several additional stock colors – blue, green, olive, white, red, yellow and orange.

We also can add molded-in logos to any Bel-Air, and this can add an extra level of professionalism to your case. Additionally, we can add engraved plates or custom decals to any case. Case colors also can be customized. Silver and black are our standard colors, but we have several additional stock colors – blue, green, olive, white, red, yellow and orange.

As stated above, we also have the ability to fully customize the interior foam. We can provide you with custom die cuts, interior doors, windows, panel mounts, shock mounts, dividers and more all for around the same price you’d expect to pay for cases filled with foam slabs.

Order Shipping Cases Today!

At Bel-Air Cases, we are happy to design a single custom shipping case or a whole fleet of shipping cases, depending on your needs. For more than 50 years, we’ve been making quality, American-made shipping cases for equipment, and our team can design whatever you might need. To get started, just click on the Request a Quote tab on our homepage and fill out our quick contact form and a member of our team will compile your information and create a free custom cost quote for our services.